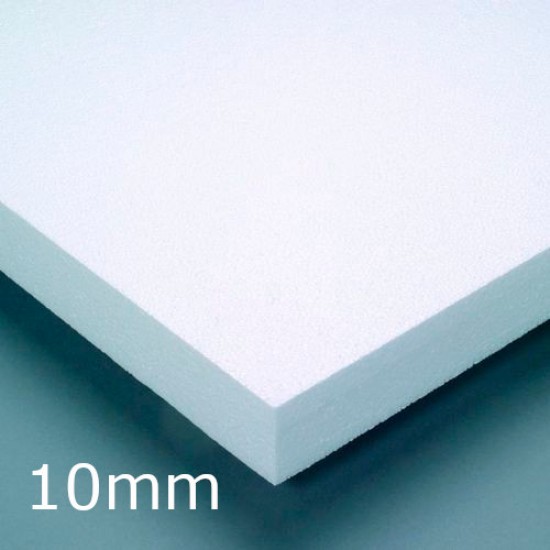

10mm White Expanded Polystyrene (EPS) for Insulated Render Systems - Ceresit CT305 (pack of 60)

- Product Code: F52

- Stock:In stock, 1-2 days

- Model: 1000x500mm - 30m2

- Weight: 3.00kg

Related Products

10mm White Expanded Polystyrene (EPS) for Insulated Render Systems - Ceresit CT305 (pack of 60)

10mm White Expanded Polystyrene (EPS) for Insulated Render Systems - Ceresit CT305 is a very lightweight and easy to handle and install, expanded polystyrene (EPS) board specially designed to be used as a part of various external wall insulation systems. It can be used in applications requiring transfer of small mechanical loads. Ceresit CT 305 White EPS Polystyrene board is an excellent insulation material for joint-less insulation systems for external walls (EWI) of buildings. This board's high resistance to tearing and shearing allows for safe insulation for all types of thin-layer renders, such as mineral renders, acrylic renders and silicate renders.

Please note polystyrene boards that we sell may not be purely white as per picture. Some of our depots may keep polystyrene with black dots (with improved performance). If you need purely white polystyrene sheets for your projects please contact us before placing an order.

- Lightweight,

- Easily cut with a sharp knife to any size and shape,

- High resistance to mould growth,

- Highly durable,

- Cost efficient,

- Environment friendly.

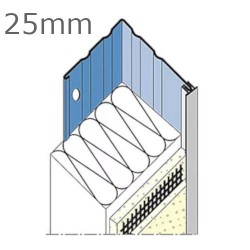

- New and existing rendered or unrendered masonry,

- Timber backed walls, floors and roofs.

- Cavity wall construction,

- On layered external walls,

- In places likely to develop thermal bridges,

- On beams and under slabs

- In balconies and loggias,

- Under roofs and between rafters

INSTALLATION

- Can be fixed to masonry or timber with mortar or adhesive, or mechanically fixed.

- Can be covered with render or siding.

- The outer surface of the board needs to be rasped or sanded down to produce an abrasive surface, before covering it with the fibre mesh, to which the base coat or mortar layer would be applied.

CERTIFICATION

- EN 13163:2004 compliant