10mm Cedral Lap Fibre Cement Cladding Board - Standard Painted - Wood Effect

- Product Code: A1-2633

- Delivery Time: 5 - 7 days

- Brand: Etex Exteriors (Tech. support: : 01287501505)

- Model and Size: 190x3600 - 0.68m2

- Weight: 11.20kg

10mm Cedral Lap Fibre Cement Cladding Board - Standard Painted - Wood Effect

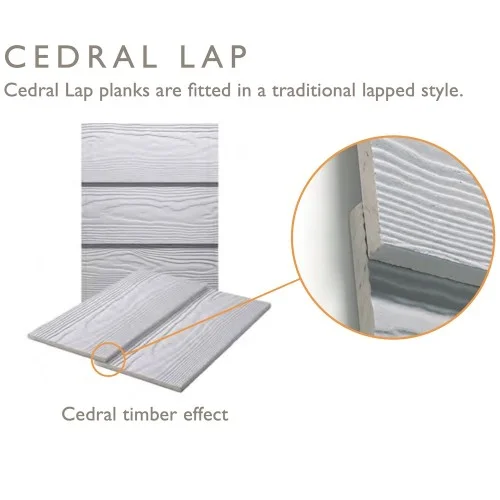

Cedral Lap is an attractive, fibre cement cladding board which is an ideal low maintenance, rot free alternative to all types of traditional cladding, but with the visual appeal of natural timber. Cedral Lap is fitted in traditional lapped style. These boards are installed to the ventilated rainscreen principle - air can flow in at the base of the system, behind the cladding and then out, over the top of the weatherboard system. This air flow behind the weatherboard enables the system to remove moisture. Cedral Lap is available in 21 factory applied colours.

It is advisable to add 5-10% wastage allowance and add extra boards for window reveals depending on reveal depth.

Usage: 1.75 boards per m2

Available in two finishes: timber and smooth textures. Smooth Cedral planks are available in full pallet quantity and extended lead time. Please check by phoning in.

CHARACTERISTICS

- Looks like wood,

- Stands up to the harshest weather conditions,

- Resistant to rot,

- Immune to attack by pests and insects,

- Low maintenance,

- Easy to install,

- Easily cut with a handsaw, guillotine, electric jigsaw or circular saw.

- Colour fast,

- Matching aluminium trims,

- Limited combustibility,

- BBA certified,

- Installed life expectancy of at least 50 years,

- Can be crushed and re-used in cement manufacture.

INSTALLATION

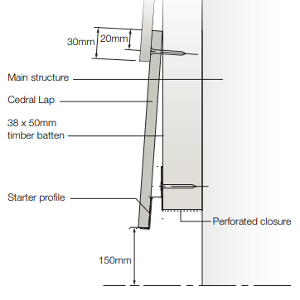

- Fix vertical timber battens to wall at 600mm centres. They should be minimum 50mm wide and have 2 planed faces. One Cedral plank must have minimum 3 battens.

- Attach perforated closures to top and bottom of battens and at door window heads to keep out birds, rodents and insects.

- Fix vertical profiles and horizontal starter profiles.

- Allow at least 150mm between bottom edge of the plank and the ground.

- Fix Cedral Lap planks. Cut them to size, where necessary.

- Place the first Cedral plank onto the starter profile. Ensure that the plank is fixed to every batten it crosses. The end of every plank must also coincide with a batten.

- Overlap the next plank by 30mm.

- Each plank must be fixed at least once to every support.

- Use one screw per support, if @ 400mm, then 11 nos, if @600mm, then 8 nos.

- The planks butt jointed against one another and the joint must coincide with a timber support. The battens should be protected with polythene under the joint.

- At corners, the planks could be overlapped, or fixed with a corner profile.

- Fix other detailing.

CERTIFICATION

- A+ rating in the BREs Green Guide to Specification,

- BBA Certificate No. 06/4299