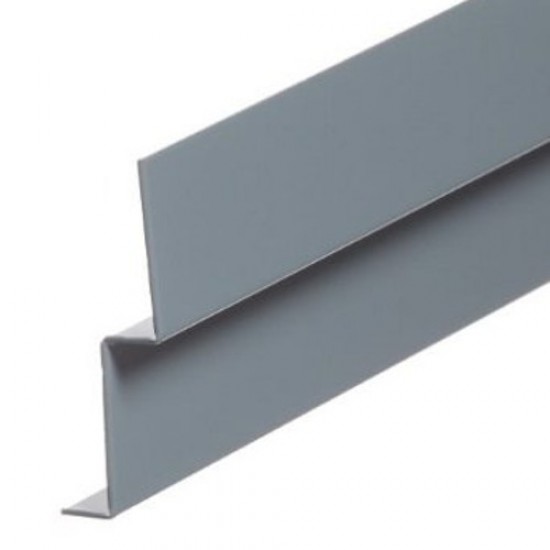

Aluminium Starter Profile for Cedral Lap - 3m length

Guide Price

Aluminium Starter Profile for Cedral Lap - 3m length

Guide Price

£20.89

£25.07 inc VAT

- Product Code: F448

- Stock:In stock, 1-2 days

- Model: 3m

Related Products

Brand: Etex Exteriors

Stock: 9999

Delivery Time: 5 - 7 days

10mm Cedral Lap is an attractive, fibre cement cladding board with the visual appeal of natural timber an alternative to all types of traditional clad..

Guide Price: £20.89

£25.07 inc VAT

Brand: Etex Exteriors

Stock: 9999

Delivery Time: 5 - 7 days

10mm Cedral Lap- Unpainted is an attractive, fibre cement cladding board with the visual appeal of natural timber an alternative to all types of tradi..

Guide Price: £15.73

£18.88 inc VATAluminium Starter Profile for Cedral Lap - 3m length

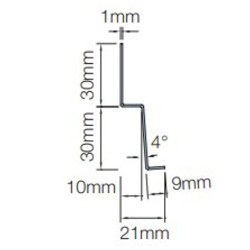

Length: 3000mm

Height: 1mm

Aluminium Starter Profile for Cedral Lap is an accessory for fixing Cedral Lap weatherboard cladding to the base structure, to start the process. Starter profile would cover the first batten with a lip and start the cladding run. Available at 3m lengths. Colour match to Cedral Lap plank is available.

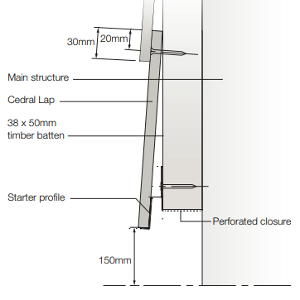

INSTALLATION

- Fix vertical timber battens to wall at 600mm centres. One Cedral plank must have minimum 3 battens.

- Fix vertical profiles and horizontal starter profiles.

- Allow at least 150mm between bottom edge of the plank and the ground.

- Fix Cedral Lap planks. Cut them to size, where necessary.

- Place the first Cedral plank onto the starter profile. Ensure that the plank is fixed to every batten it crosses.

- The end of every plank must also coincide with a batten.

- Overlap the next plank by 30mm.

- Each plank must be fixed at least once to every support.

- The planks butt jointed against one another and the joint must coincide with a timber support.

- The battens should be protected with polythene under the joint.

- At corners, the planks could be overlapped, or fixed with a corner profile.

- Fix other detailing.